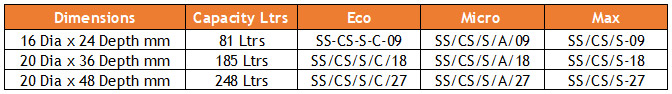

Fully Automatic Horizontal Cylindrical Steam Sterilizer (Autoclave)

*The coloumns eco micro and max are depicting model numbers so please put a main heading on top depicting model number*

*In addition to the above any special sizes are also manufactured to suit customer requirements.

- Vacuum System: Mechanical removal of air initially from within the chamber with the use of a vacuum system ensures that no air-pockets hinder the steam penetration and hence the sterilization process.

- Steam Sterilizer for sterilization of varied Hospital equipment like gloves, linen, gauze, cotton, instruments, glassware etc. using standard 121°C & 134°C cycles which are pre-programmed in the memory of the PLC / Microprocessor

- Electrical Steam-generator provided for all models up to a chamber volume of 1000 liters.

- Temperature uniformly and accurately maintained throughout the chamber to within ± 0.5°C of the Set Sterilization temperature.

- Air Filter: 0.01 micron clean air-filter for stabilization of the internal air-pressure from vacuum condition.

- Door safety: Door is automatically locked when chamber is under pressure. For double door models, both doors will not open simultaneously to ensure sterile chain integrity.

- Safety: Jacket and Chamber Safety valves provided.

- Chamber Fabrication: Chamber fabricated out of SS 304 / S316 grade steel. Heavy duty Steel Jacket encircles and strengthens the chamber.

- All machines are available with conventional hinged doors, or Modern Automatic sliding door options

- Double-wall design ensures uniform and rapid pre-heating of the chamber Flush-Mounted panel provided on the sterile side on request, ensuring separation from the un-monitored environment of the operating side.

Steam Sterilizer Sterility assurance through Automation:

- During Sterilization a Microprocessor / PLC controls temperature, Pressure, Steam Injection, Sterilization time, Drying and all other critical time based parameters.

- Important sterilization parameters like Phase Status, Current Values & set values, continuously displayed at all times on Controller Screen & on Remote Computer via SCADA software.

- Continuous display of Temperature and Pressure On-line allows user to be aware of Cycle status at all times.

- Error Code and alarm is generated and cycle stops automatically in case any error occurs. Computer Screen displays Error, possible cause and remedy.

- The advanced SCADA software provided stores detailed records of Process- Data for every cycle.

- Reports are available in Data, Summary and Graph formats for every batch of goods sterilized.