Steam Sterilizer (Autoclave)

Dimensions For horizontal rectangular autoclaves

*The coloumns eco micro and max are depicting model numbers so please put a main heading on top depicting model number*

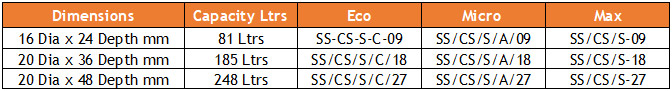

Dimensions for horizontal cylindrical autoclaves

*The coloumns eco micro and max are depicting model numbers so please put a main heading on top depicting model number*

*In addition to the above any special sizes are also manufactured to suit customer requirements.

- Vacuum System: Mechanical removal of air initially from within the chamber with the use of a vacuum system ensures that no air-pockets hinder the steam penetration and hence the sterilization process.

- Steam Sterilization: This sterilizer is designed for the sterilization of varied hospital equipment like gloves, linen, gauze, cotton, instruments, glassware, etc., using standard 121∘C&134∘C cycles which are pre-programmed in the memory of the PLC / Microprocessor.

- Electrical Steam-generator:An electrical steam-generator is provided for all models up to a chamber volume of 1000 liters.

- Temperature uniformly: Temperature is uniformly and accurately maintained throughout the chamber to within ±0.5∘C of the Set Sterilization temperature.

- Air Filter: A 0.01 micron clean air-filter is integrated for stabilization of the internal air-pressure from vacuum condition.

- Door Safety (Double Door Vertical Sliding Automatic): The double door vertical sliding automatic doors are meticulously designed for safety. The door on the operating side is automatically locked when the chamber is under pressure. For enhanced sterile chain integrity, both doors (loading and unloading) will not open simultaneously.

- Safety Features: Jacket and Chamber Safety valves are provided to ensure operational safety.

- Chamber Fabrication: The chamber is fabricated out of SS 304 / S316 grade steel. A heavy-duty steel jacket encircles and strengthens the chamber, contributing to its durability and safety.

- Door Options: This machine specifically features modern Automatic vertical sliding door options, offering ease of use and space efficiency.

- Double-wall Design: A double-wall design ensures uniform and rapid pre-heating of the chamber.

- Flush-Mounted Panel: A flush-mounted panel can be provided on the sterile side upon request, ensuring separation from the un-monitored environment of the operating side.

Steam Sterilizer Sterility Assurance through Automation:

- Precise Control: During sterilization, a Microprocessor / PLC controls temperature, pressure, steam injection, sterilization time, drying, and all other critical time-based parameters, ensuring a highly accurate and repeatable process.

- Continuous Monitoring: Important sterilization parameters like Phase Status, Current Values & Set Values, are continuously displayed at all times on the Controller Screen & on a Remote Computer via SCADA software.

- Real-time Awareness: Continuous display of Temperature and Pressure on-line allows the user to be aware of the Cycle status at all times.

- Error Management: An error code and alarm are generated, and the cycle stops automatically in case any error occurs. The Computer Screen displays the Error, its possible cause, and a remedy, facilitating quick troubleshooting.

- Reporting: Reports are readily available in Data, Summary, and Graph formats for every batch of goods sterilized, aiding in quality control and compliance.